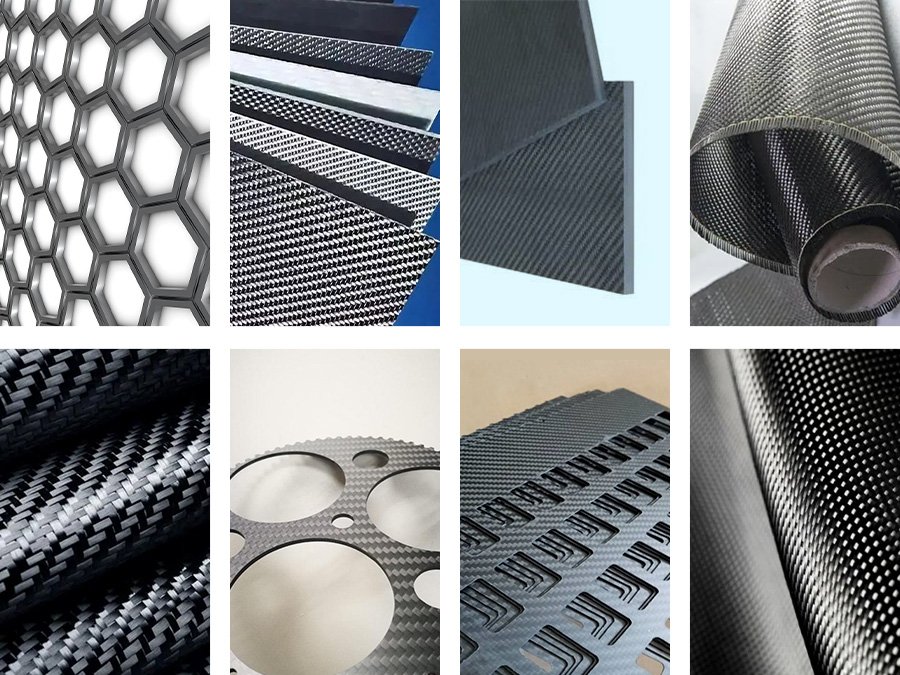

Carbon Fiber Cutting Machine for Composite Material

Digital Carbon Fiber Cutting Machine for Composite Material is used for the composite materials which are generally polymer materials with complex structure and different characteristics. The original characteristics of materials should be guaranteed in the cutting process.

The Digital Composite Material Cutting Machine (vibrating knife cutting machine) adopts blade cutting, no pollution, no impurities, anti-static treatment of the whole model, with intelligent typesetting system and intelligent error compensation system does not damage the material characteristics, has high cutting efficiency and good effect, and is suitable for laboratories, aerospace and other industries.

|

|

|

| Fixed Table Digital Knife Cutting Machine | Automatic feeding Digital Cutting Machine | Digital Cutting Machine with CCD Camera |

| Solutions | |

| Problem of Composite materials Cutting | Our Solutions of Composite materials Cutting |

| Polymer materials cannot be cut manually | Tungsten steel blade, one button for cutting material |

| Poor cutting accuracy and waste of materials | Brush motor pulse positioning, cutting accuracy ±0.01mn |

| Laser cutting smells and the material melts | Blade Cutting, Environmental Protection, No Objection Odor |

| Laser cutting smells and the material melts | Dust-free Cutting, with Cleaning System |

| High speed mirror cutting, better cutting effect | |

Technical Parameters:

| Items | BN1625, | BN1825, | BN2125, | CUSTOMIZED |

| Effective Working Area | 1600*2500mm | 1800*2500mm | 2100*2500mm | Cmr’s Request |

| Multi-function Cutting Head | The combination of Multi-function cutting head and holders by full cutting, creasing wheel,v-cut and laser red light positioning functions, CCD positioning, Camera extract large contour to cut | |||

| Multi-function Tools | Universal Drawing Tool, Creasing Wheel Tool, Full Cutting Vibrating Knife , Oblique Cutting Knife, High Power Active Round Knife, Punching Tool, Pneumatic Knife | |||

| Safety Devices | Infrared Sensing, Safe and Reliable | |||

| Moving Speed | 0-1600mm/s | |||

| Cutting speed | 0-1500mm/s | |||

| Cut Precision | ±0.1mm | |||

| Cutting thickness | 0.1-60mm(According to Different Material) | |||

| Interface | Network Port | |||

| Control Panel | LCD Touch Screen | |||

| Transmission System | Imported Servo Motor, SMTYCC linear guide | |||

| Drive system | Imported High Frequency Servo Motor | |||

| Cutting material | Knitting, Woven, PU leather, Cloth, Canvas, Sponge, Imitation Leather, Cotton Linen, Blended Fabric etc. All kinds of clothing, bags, sofa fabrics and carpet fabric | |||

| Rated Power | 2.2KW | |||

| Rated voltage | 380V±10%/220V±10% Optional | |||

| Color separation | Support | |||

| Support file format | AI、PLT、DXF、CDRetc | |||

| Material Fixed Method | Powerful Vacuum Adsorption & Intelligent partition | |||

| Auto feeding system | Vacuum Sucker Adsorpting Sheet | |||

Cutting application industry:

Digital Composite Material Cutting Machine is used for the composite materials which are generally polymer materials with complex structure and different characteristics.

| Introduction of cutter head | |

|

|

| Oscillating Knife Tool

The Electrical Oscillating Tool is very suitable for cutting medium density materials. With a wide variety of blades, it can be competent for cutting most flexible materials. Applicable: Corrugated, Cardboard, Foam board, Honeycomb board, Car Mats, Seat Cover, KT board, Gray board, Leather, Fabric, Carpet, Composite Materials, etc

|

|

|

|

| Drag knife

By dragging and cutting, it is suitable for membrane materials, medical membranes and other industries to avoid vibration marks. Applicable industries: membrane materials, medical industry and other industries

|

|

|

|

| Circular knife

Circular knife puts the materials by the high-speed rotating blades driven by the servo motor.The tool can be installed with circular blades and decagonal blades .etc which are especially suitable for cutting woven materials. Applicable industries: Leather, Textiles, Fabric, No-woven Fabric, Fur, Multi-layer, Carpet, Sporting Goods and other industries

|

|

|

|

| Pneumatic knife

Driven by compressed air,Pneumatic Knife Tool with 6mm stroke, is especially for cutting hard and compact materials. Equipped with different kinds of blades,it can make different process effect.The tool can cut the material up to 110mm by using specialized blades Applicable industries: Rubber Board , PTFE , Graphite Board, Asbestos Board, Asbestos Free Board, Fluorine Rubber Board, Sound Insulation, etc |

|

|

|

| V-Cut Tool

Specialized for V-cut processing on corrugated materials,AOL v-Cut Tool can cut 0°,15°,22.5°,30°and 45°. Applicable industries: Soft board, KT board , Corrugated Board, Packing Box, Slotting of corrugated boxes, Medium-density Material V cuts, carton packaging, Hard Cardboard, Gift Boxes, etc |

|

|

|

| Line pen

The servo motor controls the up, down, left and right movement, and scribes and marks before cutting. Applicable industries: clothing, fur, luggage, sofa and other industries

|

|

|

|

| Milling Knife

The high-frequency rotation of the blade is driven by the servo motor to cut off the material, which is mostly used for materials with large thickness of the hardness machine Applicable industry: sealing gasket, advertising packaging, etc

|

|

|

|

| Special tool for semi piercing cutting

It is used for label cutting, especially semi threading cutting, and has perfect accuracy in cutting depth. The special cutting tool for semi threading adopts variable pressure technology to support accurate cutting of labels without damaging the underlying materials. In addition to commonly used labels and other films with a maximum thickness of 3mm, this tool can also be used to cut thin paper and card paper. The special half through cutting tool can be equipped with a fixed tool protective sleeve for through cutting cardboard and diamond grade labels. |

|