Exploring the Benefits of Rubber Gasket Cutting Machines for Industrial Applications

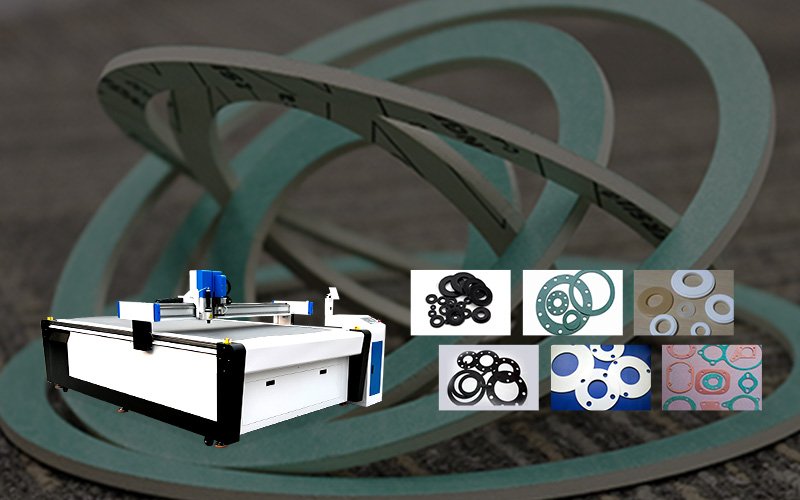

Rubber gasket cutting machines have become an increasingly important tool for industrial applications in recent years. By providing a reliable and cost effective way to cut rubber gaskets, these machines have been able to increase efficiency, reduce costs, and improve the accuracy of gasket cutting.

One of the major benefits of using a rubber gasket cutting machine is its ability to quickly and accurately cut a wide range of gaskets. Traditional cutting methods, such as manual cutting, can be time consuming, inaccurate, and costly. With a rubber gasket cutting machine, the process is much faster and more precise, allowing for the production of gaskets with a higher level of accuracy and consistency.

Another benefit of using a rubber gasket cutting machine is the improved safety and efficiency they offer. Manual cutting can be dangerous, as it requires handling sharp blades and other tools. On the other hand, rubber gasket cutting machines are fully automated and require minimal manual intervention, making them much safer than traditional cutting methods. Additionally, rubber gasket cutting machines can be programmed to quickly and accurately cut multiple gaskets in a single operation, greatly reducing the time and effort involved in the process.

Finally, rubber gasket cutting machines offer a more cost effective solution than traditional cutting methods. By eliminating the need for manual labor and reducing the amount of time required for cutting, rubber gasket cutting machines can help to reduce costs significantly. Additionally, the improved accuracy of gasket cutting provided by rubber gasket cutting machines can result in fewer problems down the line, reducing the need for expensive repairs or replacements.

In conclusion, rubber gasket cutting machines are an invaluable tool for industrial applications. By providing a safer and more efficient way to cut rubber gaskets, they can help to reduce costs, improve accuracy, and increase productivity. For these reasons, rubber gasket cutting machines are becoming increasingly popular in the industry.

The Impact of Automated Gasket Cutting Machines on Productivity and Efficiency

Automated gasket cutting machines are revolutionizing the way businesses produce gaskets for their products. By automating the cutting process, these machines are providing increased productivity and efficiency for companies in a variety of industries.

The introduction of automated gasket cutting machines has significantly improved the speed and accuracy of the gasket cutting process. By eliminating the need for manual labor, businesses are able to drastically reduce the amount of time and resources it takes to produce gaskets. Automated machines are also capable of producing a much higher quality product than their manual counterparts. This results in a much more reliable product for the customer, as well as increased efficiency for the company.

The cost savings associated with automated gasket cutting machines are also significant. By eliminating the need for manual labor, businesses can reduce the cost of labor and overhead associated with producing gaskets. Furthermore, automated machines are able to produce a more consistent and reliable product, resulting in fewer returns and lower costs for the company.

Finally, automated gasket cutting machines also provide businesses with increased flexibility and scalability. By automating the cutting process, businesses can scale up their production quickly and efficiently to meet demand. This increased flexibility allows businesses to respond quickly to changes in the market and production needs, resulting in a more efficient operation.

In conclusion, automated gasket cutting machines are revolutionizing the way businesses produce gaskets. By providing increased productivity, efficiency, and cost savings, these machines are providing a valuable solution for businesses in a variety of industries.

How to Choose the Right Rubber Gasket Cutting Machine for Your Business

Choosing the right rubber gasket cutting machine for your business can be a difficult task. It is important to understand the features and capabilities of the various machines available in order to make the best selection to meet your needs.

The first step in selecting the right rubber gasket cutting machine is to identify what types of rubber gaskets you need to create. Different machines offer different capabilities, so it is important to know the exact shape, size, and thickness of the gaskets you need to produce. Knowing the exact specifications of the gaskets you need will help you narrow down the selection of machines available.

The next step is to determine the cutting speed and accuracy required for your application. Many machines offer variable cutting speeds and accuracy based on the type of rubber gasket material you are working with. If you need to make exact cuts, a CNC machine may be the best choice. If you need to quickly cut many gaskets, however, you may need to choose a machine with a higher cutting speed.

You also need to consider the power source of the machine. Many rubber gasket cutting machines are powered by electricity or compressed air, but some come with their own power sources such as gas or diesel engines. Depending on the type of work you are doing, it may be beneficial to select a machine with an independent power source.

Finally, you need to consider the cost of the machine. Rubber gasket cutting machines range in price from a few hundred dollars to many thousands of dollars. It is important to select a machine that meets your budget while also providing the features and capabilities you need.

By carefully considering the type of rubber gaskets you need to produce, the cutting speed and accuracy requirements, the power source, and the cost, you can select the right rubber gasket cutting machine for your business. With the right machine, you can ensure that your gaskets are produced with precision and accuracy, saving you time and money.