Introducing Aramid Fiber Cloth Cutting Machines: What You Need to Know Benefits of Aramid Fiber Cloth Cutting Machines for Industrial Manufacturers

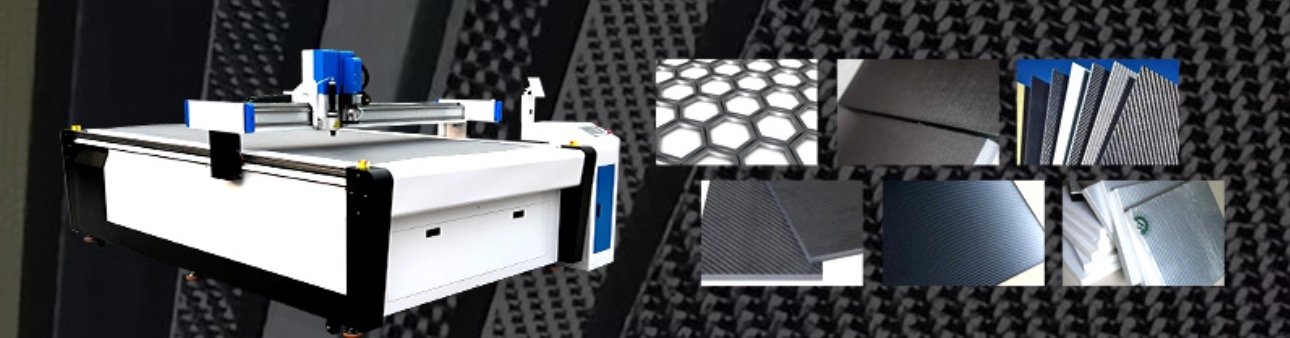

Aramid fiber cloth cutting machines are becoming increasingly popular among industrial manufacturers for their ability to provide precise cuts and high-quality results. These machines are designed to cut aramid fibers, which are strong and lightweight synthetic fabrics commonly used in the industrial sector. By using aramid fiber cloth cutting machines, industrial manufacturers are able to create parts with consistent quality and accuracy.

Aramid fiber cloth cutting machines offer several advantages to industrial manufacturers. Firstly, these machines reduce labor costs, since they are capable of cutting multiple layers of fabric at once. This eliminates the need for manual labor to cut each individual layer, which saves time and money. Secondly, these machines also increase accuracy and consistency of the cut pieces, making it easier to achieve high-quality results. In addition, aramid fiber cloth cutting machines can be programmed to cut a variety of shapes and sizes, allowing manufacturers to create custom parts that are more precisely tailored to their needs.

Another advantage of aramid fiber cloth cutting machines is their ability to reduce the amount of scrap material produced. By accurately cutting fabric and avoiding excess waste, manufacturers can reduce their production costs. Furthermore, these machines are also highly durable and require minimal maintenance, making them a cost-effective long-term investment.

Overall, aramid fiber cloth cutting machines offer a wide range of benefits to industrial manufacturers. By providing precise cuts and high-quality results, these machines can help manufacturers save time and money, while also reducing the amount of scrap material produced. With their durability and easy maintenance, these machines offer a long-term and cost-effective solution for industrial manufacturers.

Understanding the Different Types of Aramid Fiber Cloth Cutting Machines and Their Uses

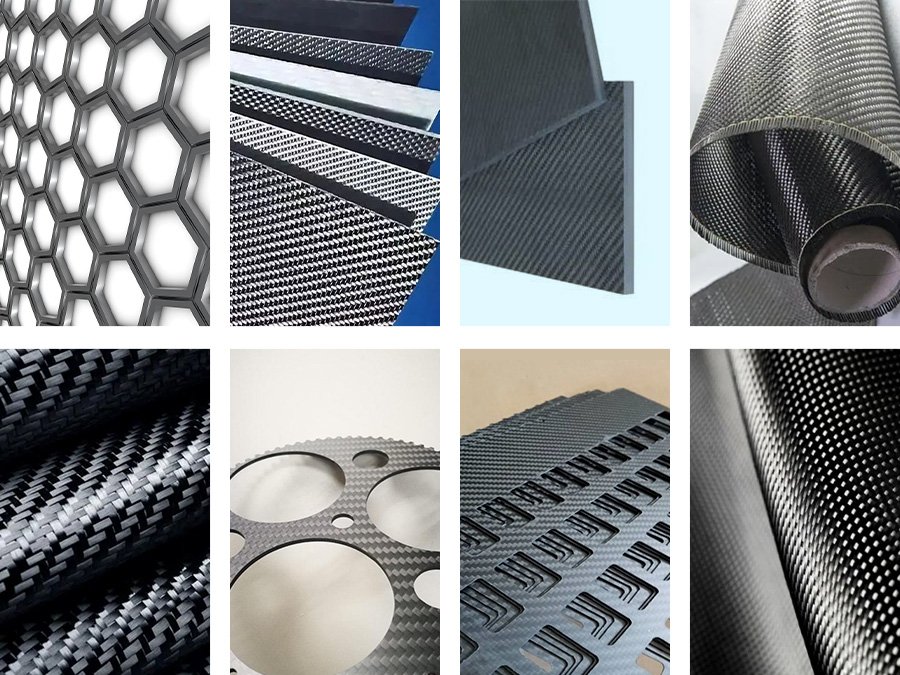

Aramid fiber cloth cutting machines are used to precisely and accurately cut aramid fiber cloth into a desired shape or size. They are used in a variety of industries, from aerospace to automotive and even military. Aramid fiber cloth is a strong, abrasion-resistant material that is heat and flame resistant, making it ideal for many applications.

When it comes to choosing the right aramid fiber cloth cutting machine for a specific job, there are several different types to choose from. Here is an overview of the different types of aramid fiber cloth cutting machines and their uses:

1. Laser Cutting Machines: Laser cutting machines use a focused beam of light to cut through aramid fibers. This type of machine is often used in the aerospace and automotive industries where precision and accuracy are critical.

2. Waterjet Cutting Machines: Waterjet cutting machines use a high-pressure stream of water to cut through aramid fiber cloth. They are typically used for cutting complex shapes and intricate details.

3. Plasma Cutting Machines: Plasma cutting machines use a high-intensity beam of plasma to cut through aramid fiber cloth. This type of machine is often used in the automotive and military industries.

4. Ultrasonic Cutting Machines: Ultrasonic cutting machines use a vibrating blade to cut through aramid fiber cloth. They are often used in the medical industry, due to their ability to cut through delicate fabrics with precision and accuracy.

No matter which type of aramid fiber cloth cutting machine you choose, it is important to ensure that it meets your specific needs. The right machine can make a big difference in the quality of the finished product, as well as the time it takes to complete the job.